-

About

-

Products

- By Timber Product

- Cladding

- Decking

- Joinery

- Screening

- Panelling

- View all

- By Application

- Exterior Cladding / Siding

- Exterior Rain Screen

- Exterior Roofing

- Interior Walls & Ceilings

- Soffits

- Screening, Fins & Battens

- Windows, Doors & Joinery

- Posts & Beams

- Accessories + Samples

- Coatings

- Fixings

- Samples

-

Shop

- Samples

- Timber Samples

- Architectural Sample Box

- View all

- Accessories

- Coatings

- Fixings

- View all

-

Resources

- By Resource Type

- Technical Data Sheets

- Guides & Manuals

- Technical Articles

- Profile Drawings

- View all

- How To

- How To Specify

- How To Install

- How To Maintain

- Projects

- Contact

Modern Versions of Shiplap Timber Cladding

Shiplap cladding is a time-honoured method to create a weather-tight exterior timber siding. But what’s the best shiplap profile?

Shiplap cladding is a time-honoured method to create a weather-tight exterior timber siding. A rabbet or overlap is created in the timber profile – providing weather proofing to an exterior façade.

Dating back to the 5th century, shiplap style timber cladding was a favoured building material for Anglo-Saxon homes in the United Kingdom.

This style of construction was brought to New Zealand and Australia by British immigrants and was used extensively throughout the 1800s – primarily using locally grown native timbers.

Over the last 50 years plantation pine has been used for shiplap cladding along with stable, naturally durable softwoods such as Cedar and Redwood.

Traditional vertical shiplap has a nail fixed through the face of the board, pinning the board to its frame, along with the proceeding board.

Typically the overlap required is greater than 20mm and an expansion gap is required to allow movement of the wood in service. In some countries, for example New Zealand, a weather groove may be required to reduce the chance of moisture ingress.

Traditional Vertical Shiplap

The downside of face fixing shiplap cladding is that that there is a visible fixing head, and this may lead to moisture working its way into the timber. In some cases where a paint finish is employed, the nail may be punched and filled – this also can become a weak point in the façade.

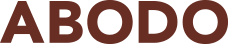

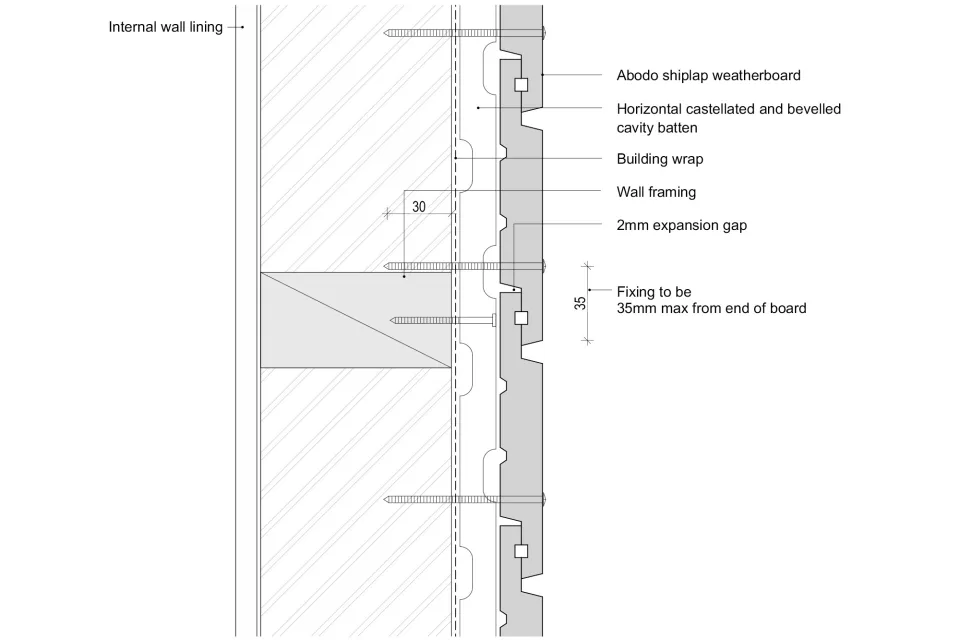

Modern versions of shiplap cladding use a concealed fix method – where a tongue and groove system interlocks to hold the board in place, and a large overlap creates a traditional shiplap look. Fixing takes place through the tongue and the fixing is not exposed to weather. These systems avoid the penetration of the timber through its face – reducing possible moisture penetration.

Concealed Fix Shiplap

This kind of interlocking profile will only succeed with stable timber. Timbers that shrink, expand and cup in weather will eventually fail in an interlocking profile, causing weather tightness problems.

Abodo’s Vulcan Cladding is one timber that is stable enough for an interlocking shiplap profile, it’s thermally modified for stability and grain oriented for consistent performance.

When considering shiplap style timber cladding, it is worth considering the pros and cons of a traditional shiplap profile and a concealed fix, we summarise these below:

Pros for a Traditional Shiplap Profile:

- Time proven

- Easily fixed, but does require careful alignment of fasteners

- Does not require high stability timber

- Easily remove one board

Cons for a Traditional Shiplap Profile:

- Exposed head can oxidise and create stains on surface

- Moisture ingress around fastener may lead to premature decay

- Filler required around paint finish

Pros for a Concealed Fix Shiplap Profile:

- Easily fixed, does not require absolute alignment of fasteners

- Fastener is not exposed to the weather

- Clean appearance without visible fastners

Cons for a Concealed Fix Shiplap Profile:

- Requires stable timber

- Difficult to remove one board

What is the best cladding profile option for your project? Consider the look and the level of exposure your cladding will have. Timber choice is critical - the best timber claddings are lightweight, stable and durable and preferably available with a concealed fixing detail. Visit the Abodo Cladding range to consider your options.