-

About

-

Products

- By Timber Product

- Cladding

- Decking

- Joinery

- Screening

- Panelling

- View all

- By Application

- Exterior Cladding / Siding

- Exterior Rain Screen

- Exterior Roofing

- Interior Walls & Ceilings

- Soffits

- Screening, Fins & Battens

- Windows, Doors & Joinery

- Posts & Beams

- Accessories + Samples

- Coatings

- Fixings

- Samples

-

Shop

- Samples

- Timber Samples

- View all

- Accessories

- Coatings

- Fixings

- View all

-

Resources

- By Resource Type

- Technical Data Sheets

- Guides & Manuals

- Technical Articles

- Profile Drawings

- View all

- How To

- How To Specify

- How To Install

- How To Maintain

- Projects

- Contact

Introducing New Growth ™ Feature Timbers, and a bold new look too.

17.11.2023

Comparing Different Coatings Across Cuts of Timber

John Kilby from Resene Coatings Technologies compares different coatings across cuts of timber to analyse performance.

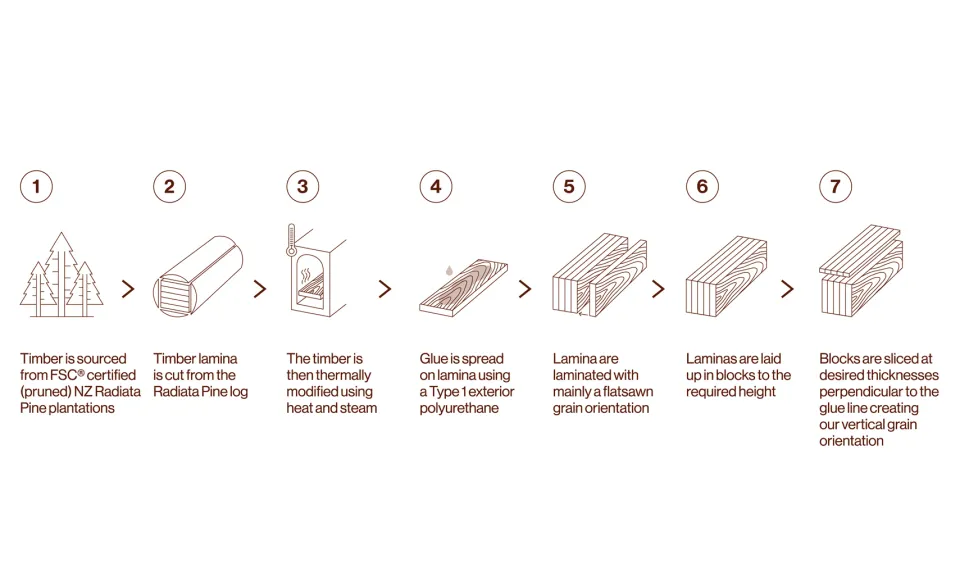

We were recently lucky enough to host a webinar by John Kilby from Resene Coatings Technologies, who took us through his research into the relationship between different types of timber, cutting methods and coatings, and how these relate to performance over time.

Beginning with an informative overview of trees and their structure, and how this interacts with timber products in terms of density, stability and appearance, John’s webinar held many lessons for those working with timber and, particularly useful for Abodo, an overview of how different coatings relate to longevity.

Here is an overview of the learnings from the webinar.

The structure of the tree

A keen knowledge of trees and how they grow in nature should inform cutting methods to take into account the tree’s internal structure. Stability is increased through quarter sawing, John says, but there is more wasted timber in this method than if half-sawing is used. He also points out that movement due to moisture changes will be greatest along growth rings, and this is the reason that certain cuts result in warping, cupping, bowing, kinking and crooking of a timber board more than others.

This knowledge is the reason Abodo developed their patented vertical grain orientation technology in their timber processing methods.

The location of the tree and the timber

He discussed how trees will grow differently depending on where they are located, in terms of moisture content and stability. This relates to the products created from these timbers and their application in different climates. For instance, weatherboards used on a house in Dunedin will behave differently to those used in Northland due to these areas having different climates. Stabilising the timber before it is placed on the house will reduce these location-based differences, which is why Abodo Vulcan uses thermal modification, locking in 7-8% moisture resulting in less shrinkage on site as the timber settles. Also, allowing timber the space for movement and air flow through sound weathertight design will enable the timber to last longer in application.

Replacing the bark

As bark is removed in order to create a piece of timber for building, that protective layer must be replaced to shield the timber from the outside world. To illustrate his analysis of coatings, John delved into how different products absorb into the cellular structure of the timber and the results of this. Using a piece of filter paper, which is also made of cellular fibres like timber, he tested water borne versus oil based stains. His experiment showed that oil based stains penetrate further as they take longer to dry on the paper. He then tested mineral based oils, which penetrated further still, but are problematic due to using petrochemicals. Abodo’s Protector coating is a penetrating oil stain that is water borne, which John stated is the best of both worlds.

Comparing coating methods

No coating will result in the natural progression of mould and fungal growth and the deterioration of the timber.

Vegetable oils require fungicides to work well, as their natural derivations increase mould growth. These are also drying for the timber, reducing longevity. Many of these oils require a lot of processing and modification to have a good result.

Mineral oil stains will give a natural look that is highly penetrating, but require regular maintenance. They also cannot be re-stained, with a different stain, or painted at a later date due to the absorption of the mineral oil. They can also be harmful to humans and the environment.

Penetrating semi transparent stains can be re-stained or painted but also require regular maintenance to restore the timber to a beautiful finish.

Film-based stains have an initially appealing result but commonly crack with exposure to UV allowing moisture to sit between it and the timber causing damage, the result of eroding away the timber underneath over time.

Paint reflects UV rays and therefore protects the timber underneath, due to its opacity

Refining finish

The durability of any stain is also related to the finish, says John. While a dressed finish may look smooth, a bandsawn finish, in which the wood fibres stand upright, will absorb more of the stain or oil, resulting in a longer lasting finish that requires less maintenance.

This is the reason Abodo offers a bandsawn finish, which combined with the quarter sawn timber, results in optimal longevity and durability. Abodo also offer a brushed finish for a varied aesthetic that still allows as much stain to penetrate as possible.

Abodo Protector

Abodo worked with Resene to test and formulate our Protector coating for exterior timber application, with the aim of having a natural finish with the lowest toxicity possible, but delivering high level performance and protection. This consultation informed our choice to create this water-based penetrating stain. Despite the recoat period for penetrating stains generally being 18-24 months, we find our Abodo Protector range can last up to four years with even weathering across the wall due to the consistent vertical grain of the timber.

We would like to thank John Kilby for sharing his wide knowledge about trees, timber and coating methods.

Recent news

NZ Lead Times 2025

Lead times for our main Vulcan® Cladding, Decking, Screening and Panelling lines.

Free Decking Screws with Every Vulcan Decking Order*

It’s now quick and easy to install a Vulcan timber deck, with a one week lead time** (uncoated) and free Abodo Decking Screws for each order*.

Meet Laurens Notenboom

Laurens joins Abodo’s growing international team as our new Head of Sales – APAC, UK & Europe.

Meet India Thorp

India Thorp joins Abodo's senior leadership team as General Manager – Sales to help grow markets in New Zealand, the Pacific Islands and North America.